FAQ

1. Introduction:

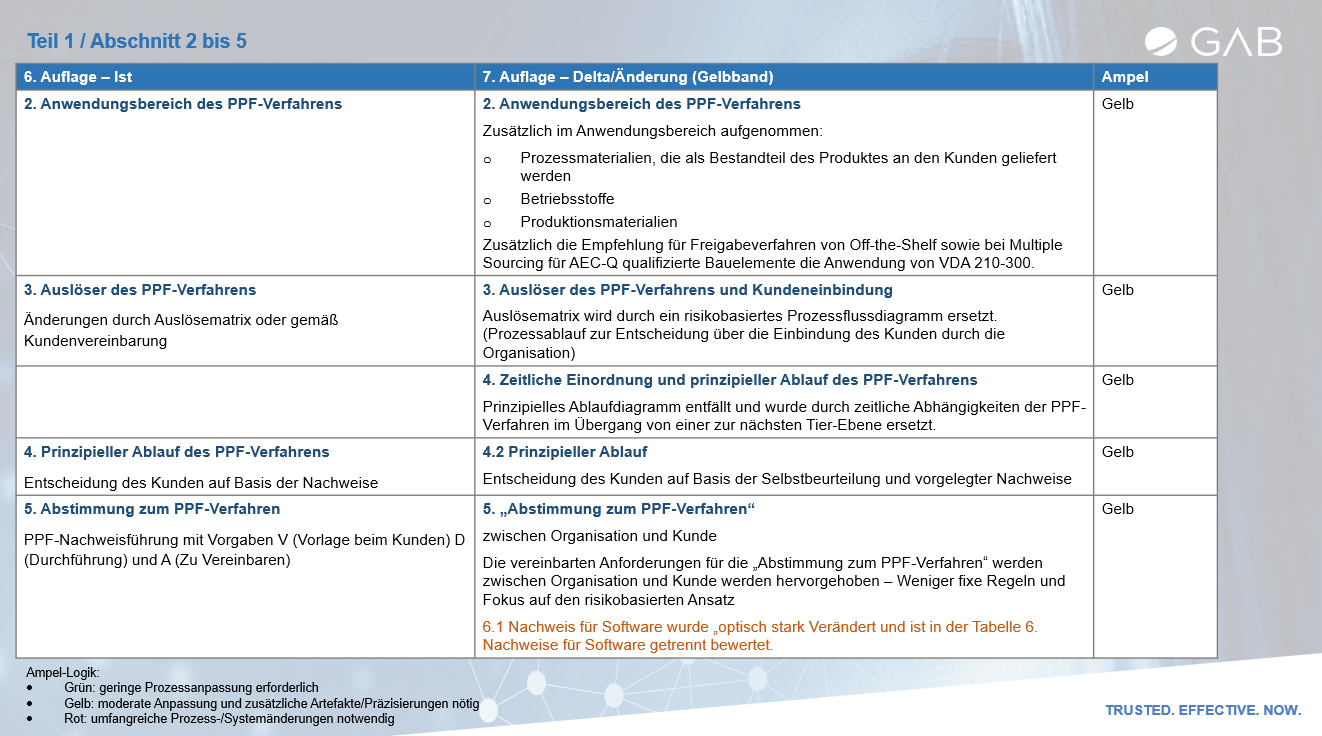

The VDA has published a revision (yellow volume) of Volume 2 – Production and Process Assurance.

The yellow volumes are not final and offer the entire supply chain – i.e., every company that uses the volume – the opportunity to submit an objection.

The objection may relate, for example, to effort, comprehensibility, wording, etc. Of course, the objection must be qualified and well-founded.

It will then be reviewed by the project group, which will either accept or reject it, and provide feedback to the submitter.

The link to download the volume and the feedback form is as follows:

https://vda-qmc.de/publikationen-und-apps/gelbbaende/

2. Summary:

VDA Volume 2 describes the production process and product approval procedure (PPF) as a central instrument for ensuring the quality of products and production processes in the automotive supply chain. The aim of the PPF procedure is to provide verifiable evidence that all requirements agreed between the organization and the customer have been met and that trouble-free series delivery can be guaranteed.

The PPF procedure comprises the equivalent components of production process approval and product approval.

The organization is responsible for implementing the PPF process. This applies to both its own production processes and outsourced processes and purchased parts along the supply chain. Results from upstream PPF processes (e.g., Tier n suppliers or PPAP) can be integrated.

A central principle of the 7th edition is the risk-based approach. The scope, depth, and type of evidence are based on the risk of the product or change and are no longer fixed. This reduces complexity and documentation effort while ensuring quality and traceability.

3. Why a new edition?

· Increasing complexity of products and supply chains

· Focus on risk orientation instead of document volume

· Harmonization with IATF 16949, OEM requirements, and international procedures (e.g., PPAP)

· Greater commitment, clarity, and efficiency in the PPF process

4. Significant changes:

4.1 Stronger risk-based approach

New/refined:

· The scope and depth of the PPF are consistently based on the product and change risk

· Away from "one-size-fits-all" documentation

· Focus on effectiveness rather than completeness

Management added value:

✔ Less bureaucracy, more targeted use of resources

4.2 Binding "coordination on the PPF procedure"

New:

· Requirement for early coordination between the organization and the customer (with recommended time frame)

· Determination of:

- PPF scope & evidence

- Roles & responsibilities

- Schedule, escalation & requalification

Management added value:

✔ Clear expectations, fewer escalations, and fewer additional requests

4.3 Clear separation & equivalence

Specified:

· Production process approval and product approval as equivalent components

· Both are mandatory for series approval

Management added value:

✔ Better transparency regarding process vs. product maturity

4.4 New structure of verification types

Newly introduced/standardized:

Four standardized types of evidence, flexibly combinable depending on risk:

o Self-assessment

o Reference verification

o Proof of existence

o Verification evidence

Management added value:

✔ Uniform logic, better comparability

4.5 Strengthening risk management in the event of deviations

Significantly tightened:

· Mandatory interdisciplinary risk assessment in the event of non-compliance

· Documentation and justification requirements

· No series start in case of unacceptable risk

Management added value:

✔ Greater legal certainty, reliable decisions

4.6 Clear rules for special cases

New/expanded:

· Tiered PPF procedure

· Variant and small series approvals

· Specific regulations for off-the-shelf AEC-Q-qualified electronic components

· Binding requirements for re-qualifications

Management added value:

✔ Uniform approach even in exceptional cases

4.7 What does this mean for management?

· More responsibility for risk-based decisions

· Earlier involvement in critical PPF issues

· Less formal documentation, but greater decision-making authority

· PPF is clearly positioned as a management and control tool

The 7th edition of VDA Volume 2 shifts the focus from documentation to risk, decision-making, and effectiveness—thereby strengthening quality, delivery capability, and legal certainty.

Note: Since the changes in the software description are significant, we have presented them in a separate news article.

You can find more information in our post on LinkedIn.